Our A-Z Process

|

We get it - buying furniture online can be a stressful and uncertain process. You might find yourself asking the question, "How do I know this furniture will hold up?" The concern over quality is understandable - it's difficult to get a feel for the quality of a piece if you can't see it in person. We create furniture that stands the test of time and have the standards to prove it. Our Cosmetic StandardsOur mission is to bring the beauty inherent in nature into the home and to do so in a sustainable, eco-friendly manner. In order to accomplish this, we use the entire tree to build our furniture. Because of this, there are some unique, natural imperfections that occur in every piece. We treasure these characteristics; they're representative of the life the tree has lived. Because of this, we choose to work with these imperfections, rather than buffing them out. This section covers each characteristic in greater detail. |

|

|

KnotsAs a tree grows and increases the size of its trunk, it begins to overtake the branches that grow out of it. Knots begin to form around these areas, building up the trunk as the tree begins to expand. Since the branches are still growing while the trunk overtakes them, these knots are solid and filled with living wood. Since we use the entire tree to build our pieces, knots of varying sizes and shapes will be present. Occasionally, there are natural cracks that occur within these knots. These do not affect the structural integrity of the wood and therefore are not considered defects.

|

FillerBecause the entire tree to used when constructing our furniture, some knots and/or wind cracks may need the use of filler. To do this, we use the highest quality epoxy-based filler. It's an incredibly durable filler and rated to last a lifetime. Care is taken to blend the coloration as close as possible, but areas that have been filled may be noticeable and are not considered a defect in the furniture’s finish. By using filler, it prevents us from having to waste any part of the wood in the crafting process making our pieces as sustainable as possible. |

|

|

|

GrainThe tropical hardwood species we use for our solid hardwood furniture can have extreme grain and color variations. These variations are truly a key element in the beauty of each piece and make each piece of furniture a unique work of art. As such, these variations are unavoidable and not considered defects.

|

Mineral DepositsThe presence of natural minerals such as iron, phosphate, and calcium in the soil where the tree lived often causes variations in the wood grain. These may appear as rings, circles, lines, or as darker or lighter shades than the natural grain of the wood. These factors are unavoidable and not considered defects. |

|

|

|

Natural CracksSeasonal cracks and splits may open from time to time but are considered normal in solid, tropical hardwood furniture. In most cases, the opening of natural cracks is a result of changes in environment such as humidity or sunlight. These cracks are a natural part of the wood, caused by tree movement from the wind and natural forces. As long as the crack is not excessive (the crack does not exceed 6 inches in length) it will not affect the structural integrity of the furniture and is therefore not considered a defect.

|

CheckingChecks are hairline cracks in the wood caused by natural tree movement from the wind and natural elements. This checking is inherent in the tropical hardwoods and is not considered a defect. |

|

|

Variations in climate and other factors such as air conditioning, heating, and sunlight, may cause these cracks to open and close over time, which is unavoidable and not considered a defect. Some touch ups with a stain marker may be necessary. Our Commitment to Quality Construction |

|

|

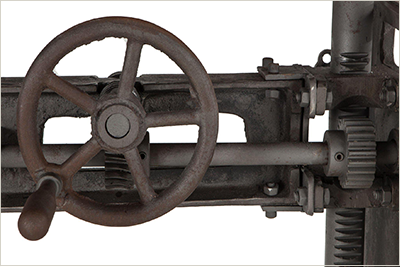

Mortise & Tenon JoineryTo us, furniture is not just a commodity - it's an art. As such, constructing furniture to our standards requires a high degree of technical accuracy and craftsmanship. Solid wood components must be allowed to expand and contract with the seasons in order to prevent cracking and ensure structural integrity. One of the key construction techniques we use is Mortise & Tenon Joinery. It's a technique that craftsmen have used for thousands of years to join pieces of wood when they're connected at a right angle. These strong and stable joints are used for many projects, from furniture to carpentry. |

|

This technique involves the carving of a Mortise hole and Tenon tongue. These pieces are then joined together and locked by a metal clip. In order for the joinery to work as intended, the Mortise and Tenon pieces must be cut with a high degree of accuracy. When done correctly, a Mortise & Tenon joint is considered to be one of the strongest joints in woodworking. |

|

Floating Panels and TopsWithin the frame, held together with Mortise & Tenons, wood panels are inserted along a tongue and groove, which allow for the natural movement of solid wood. This is an essential element of constructing quality furniture. Solid wood is a living, breathing material that expands and contracts with the seasons. Therefore, the wood must have room to breathe. The panel “floats” within the frame, meaning that no glue or nails are used to hold it in place. This delicate process prevents cracking. |

|

Hand-turned Legs and ComponentsWe believe that truly unique pieces aren't built by machines - they're built by humans. Instead of using machines to turn wood components on a lathe, each individual component is hand-carved on the turning machine. This traditional process requires a high degree of expertise and allows our artisans creative freedom to add character to each and every piece made. |

|

Dovetailed DrawersOftentimes, tried-and-true techniques developed over centuries trumps technological advancements. Dovetailing is one such example. Dovetailing is a process that involves cutting interlocking grooves into the drawer's front and side panels. In order to ease the drawer's sliding action and ensure that it doesn't get over-extended, wood (as pictured) or metal glides are implemented. This technique ensures that your solid wood piece will withstand anything life can throw at it. |

|

Dutchman Patches & Butterfly JointsIn order to sustainably build and produce high quality solid wood furniture, we often leverage the use of reclaimed wood. When working with reclaimed wood, it is oftentimes necessary to patch portions of the material that were previously used in old buildings. Butterfly joints are used in solid wood to strengthen panels and other components where cracks may be present. In addition to adding to the heirloom quality of the product, both add beauty and uniqueness to each piece. |

|

Our craftsmen take great care to match the grains and coloration of these patches to that of the wood grain as closely as possible, but some repairs are hundreds of years old as the material was repurposed over and over. Although these patches are noticeable, they reflect the extremely skilled craftsmanship necessary in order to work with reclaimed wood. Our Wood Finishing ProcessThe finishing process to furniture is oftentimes the most overlooked step in the process of furniture building. Many companies opt for cheaper, high VOC (Volatile Organic Compound) finishes. These finishes release toxic gas into the atmosphere - not just during production but in the home as well, alongside many other VOC sources in the home. In order to produce more eco-friendly and human-friendly furniture, we utilize a special low-VOC compound for our finishes. This finish serves to not only protect your family from hazardous emissions, but are also rated to be one of the most durable finishes in the market! |

Step 1: Patina LayerAfter the entire piece has been hand-planed to create a nice structure and feel to the table, the craftsman layers on a black patina. This is subsequently sanded off, but look around the piece, inside of grooves, in the notches and distressing, and you will see these dark accents. Step 2: Sanding of Patina LayerThis is a crucial aspect of the finishing process and must be done completely by hand. This ensures that just the right level of distressing and patina is present to create the old-world feel of the collection. Step 3: Sealer Coats AppliedTypically, a minimum of two sealer coats are applied to our pieces in order to ensure that your piece is protected as best as possible from the elements. Step 4: Lacquer CoatsBonds with the sealer to create a highly moisture resistant and durable finish. As with our sealer coats, we tend to apply a minimum of two coats of lacquer alongside the sealer. Step 5: Final Polishing and Touch Up |

|

|

The catalyzed process used will protect your furniture for generations. However, while this process creates a bond between sealer & lacquer layers, care still needs to be given to prevent scratching, such as: putting excessively hot items on top or using acetone/nail polish remover, which can harm the fine finish of these products. In case of damage to the finish, an authorized Mohawk repair specialist can easily remedy almost all finishes used through a simple repair process. |